Загальне

120F, 124F, 124Fa, 120Fd, 120FN, 124FN, 420Fa Groups Module 1. Forging

00-Heating_lekz.pdf

01-Classification of equipment_lekz.pdf

02-ROLLING THEORY AND PRACTICE.pdf

03-Open-Die Forging_lekz.pdf

04-Closed-Die Forging_Lecture2.pdf

04-Closed-Die Forging_Lekture1.pdf

06-extrusion lecture.pdf

Обработка металлов давлением толковый словарь.pdf

dayton_tech-stamping.pdf

PRESS DIES TUTORIAL.pdf

TEM lab work.pdf

Module 2. Welding and Allied Processes

__Technologies of Engineering Materials 2020.pdf

Labarotory Works Report book.pdf

Laboratory Work. Cold Welding.pdf

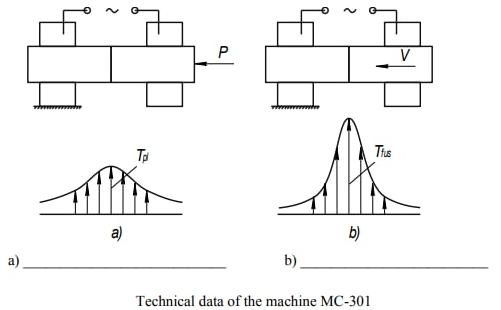

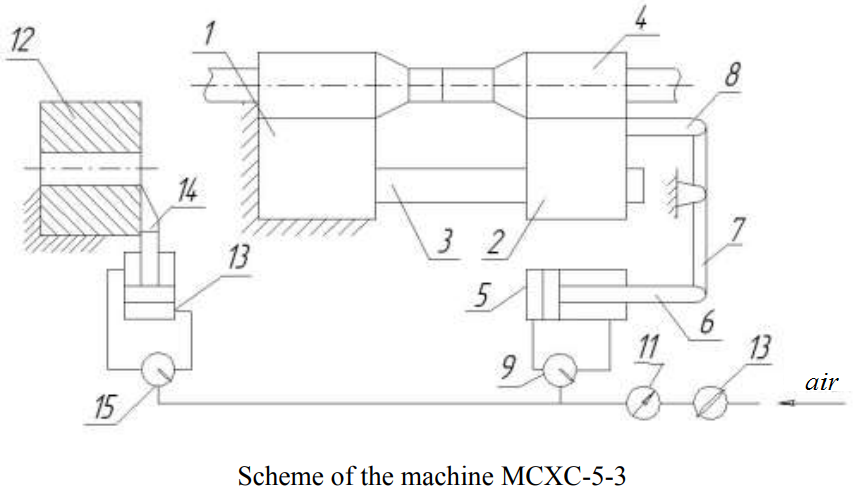

Laboratory Work. Resisrtance Butt Welding.pdf

Laboratory Work. Resisrtance Spot Welding.pdf

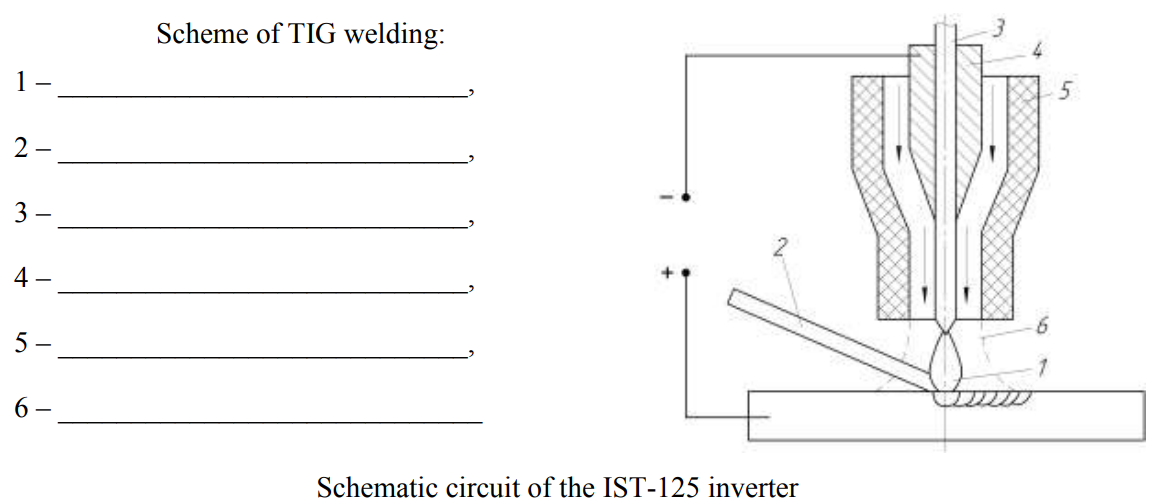

Laboratory Work. TIG Welding.pdf

Welding KhAI Manual Book.pdf

Welding Laboratory Practicum manual.pdf